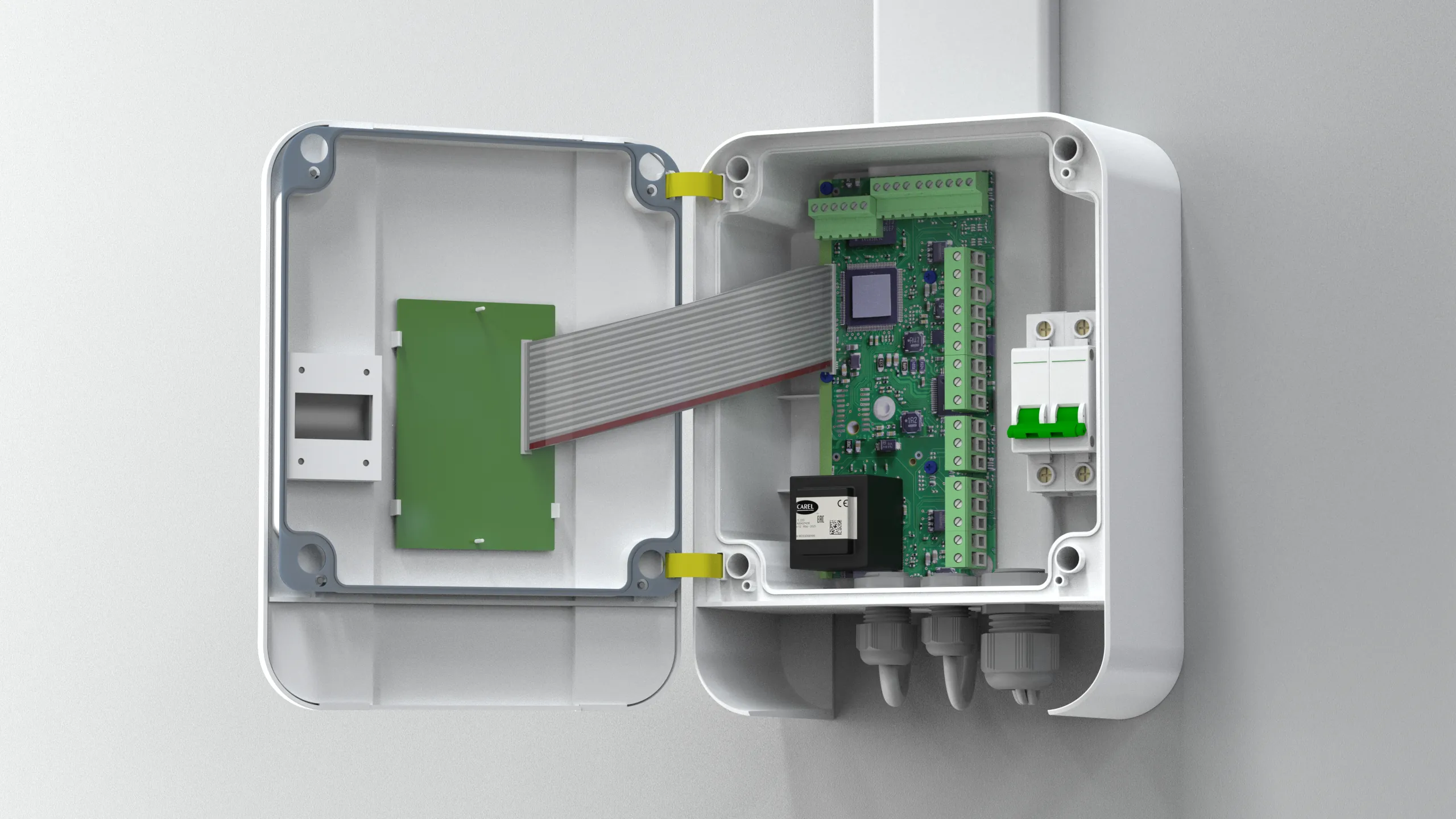

Master’s workshop during which CAREL, a company specialized in control solutions for refrigeration, challenged us to redesign the MasterCella, a control unit. The goal was to bring the product up to date, simplify installation and cable management, and introduce an innovative solution to prevent condensation on the cables from entering into the enclosure.

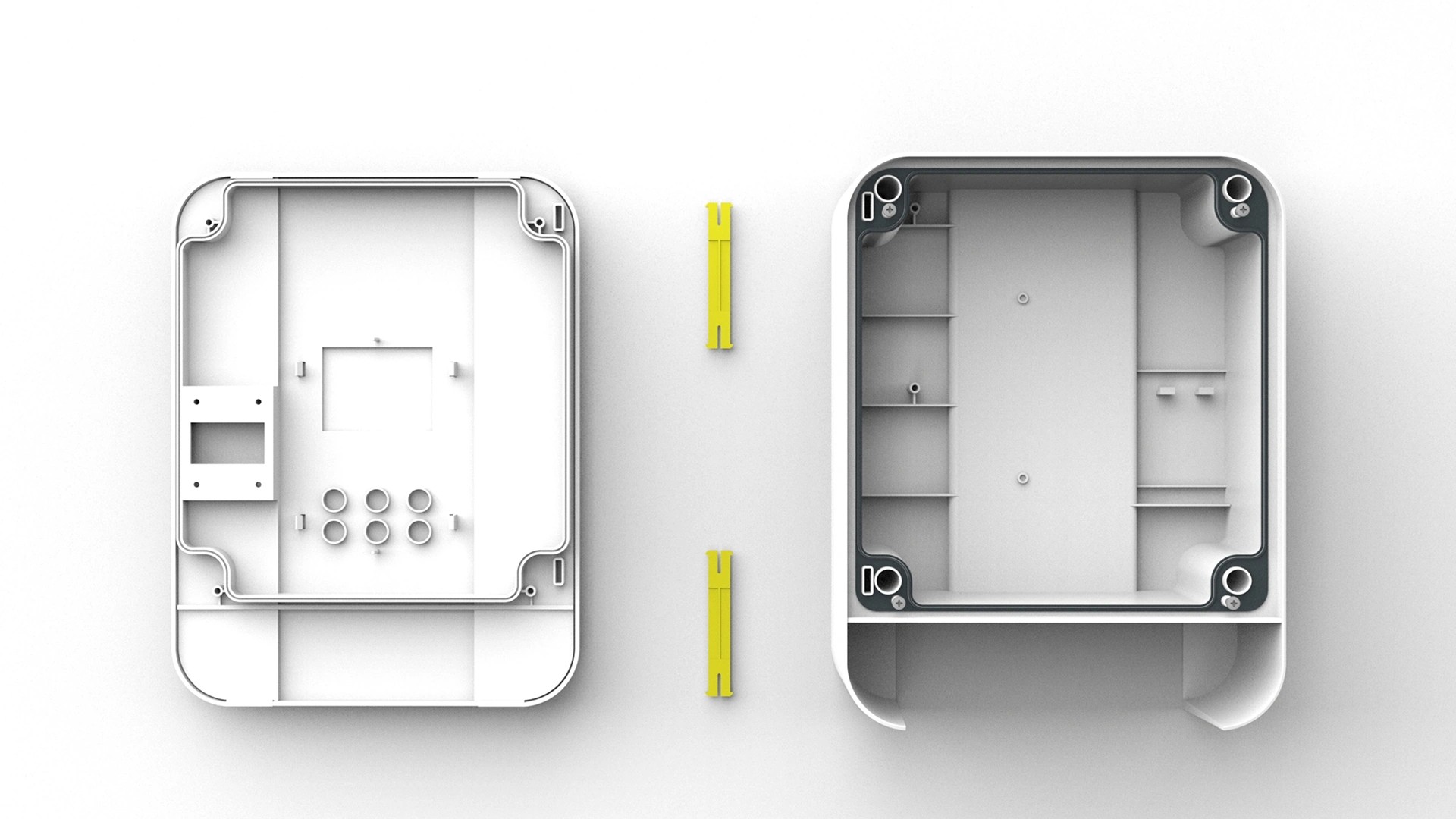

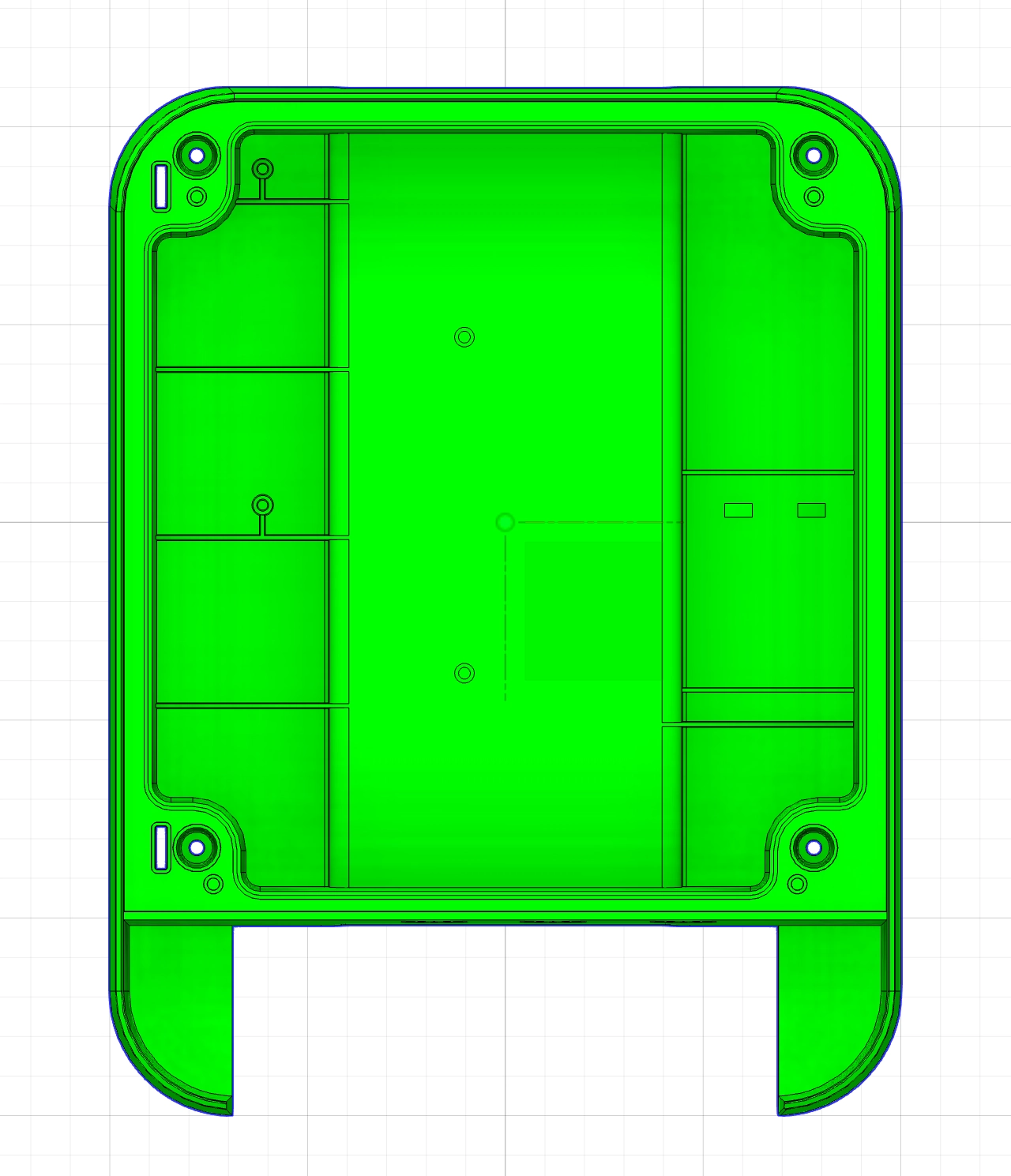

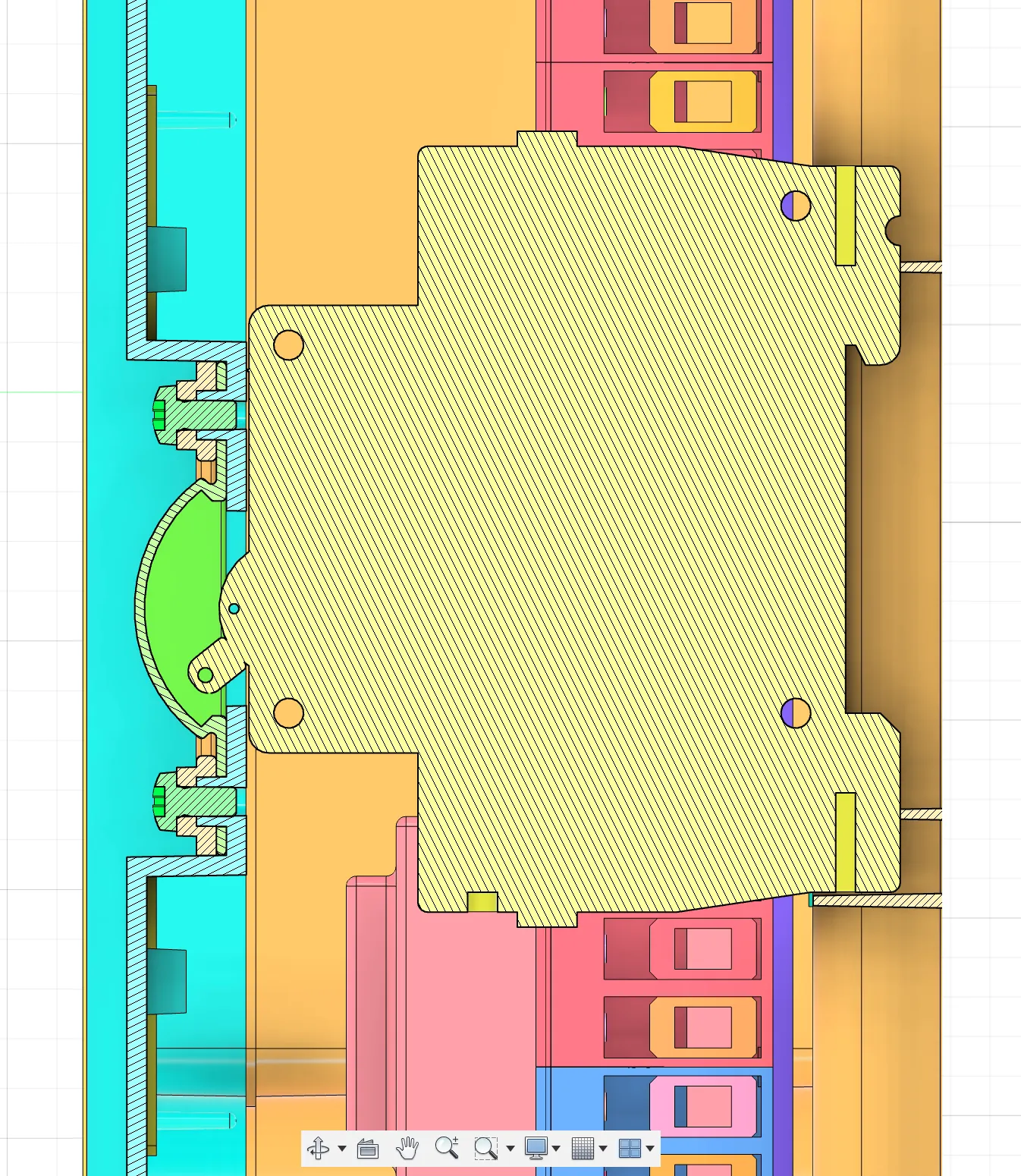

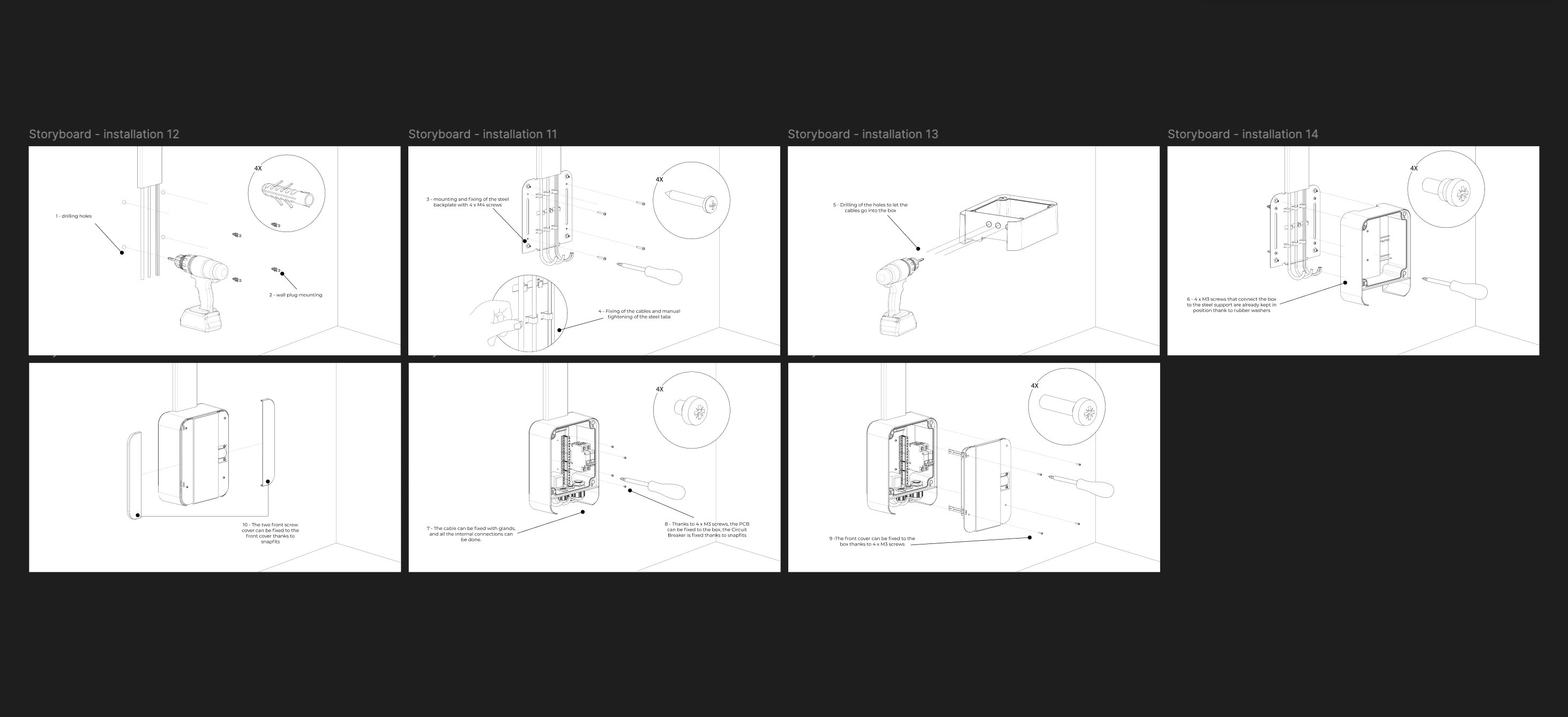

Our creative freedom was strongly limited by technical constraints that had to be respected, such as maintaining an IP65-rated enclosure, preserving specific dimensions to integrate the electronic components, and ensuring quick access to the kill switch, as weel as keeping the cost as low as possible. The final CAD model was required to be production-ready.

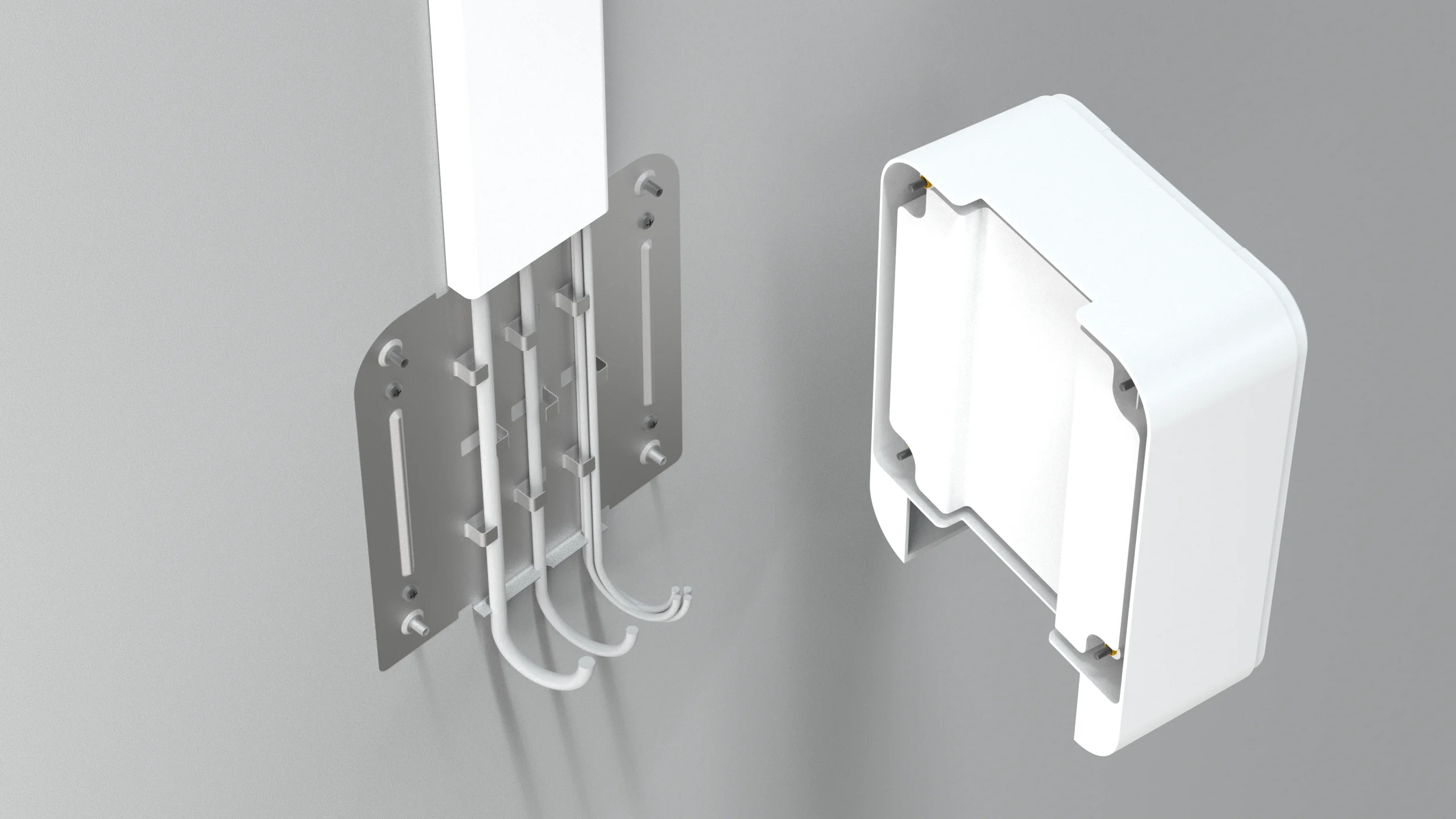

A low-cost metal sheet backplate placed between the enclosure and the wall is used to guide the wires and connect them to the bottom of the thermostat. Its purpose is to enforce cable entry from below rather than from above, preventing condensation water present on the cables from flowing into the enclosure. The smart guiding system, created through metal sheet bending and stamping, allows the technician to easily route, secure, and organize the cables.

A silicone rubber cover is used to enclose and protect the thermostat’s switch, providing a flexible yet durable barrier against dust and water ingress. This simple yet effective design choice ensures compliance with IP65 standards without compromising the switch’s accessibility or functionality.