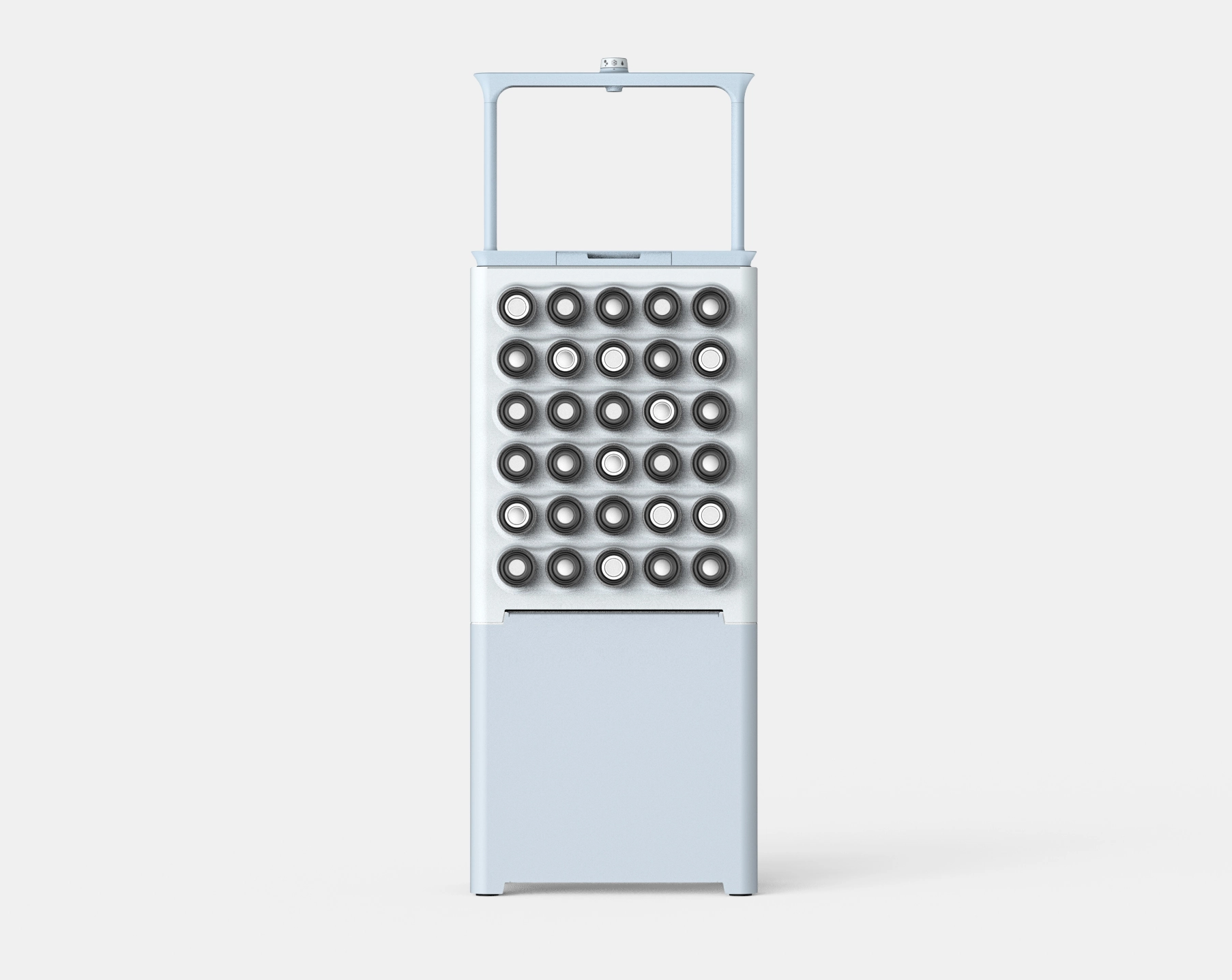

Midea is a Chinese group specializing in home appliances. As part of their collaboration with Politecnico di Milano, we were tasked with conceptualizing a water dispenser made up of three distinct modules: the top module responsible for dispensing water, the middle module for which we had to define a purpose, and the bottom module that houses the technical components such as pumps and filters.

As my thinking evolved, I wanted to base the design of this project on two key points. First, I wanted the middle module to be designed as a bottle storage unit. Second, for reasons of flexibility of use and optimization in a restaurant context, I wanted the tap of this water dispenser to be operable both from the front and from the back of the product.

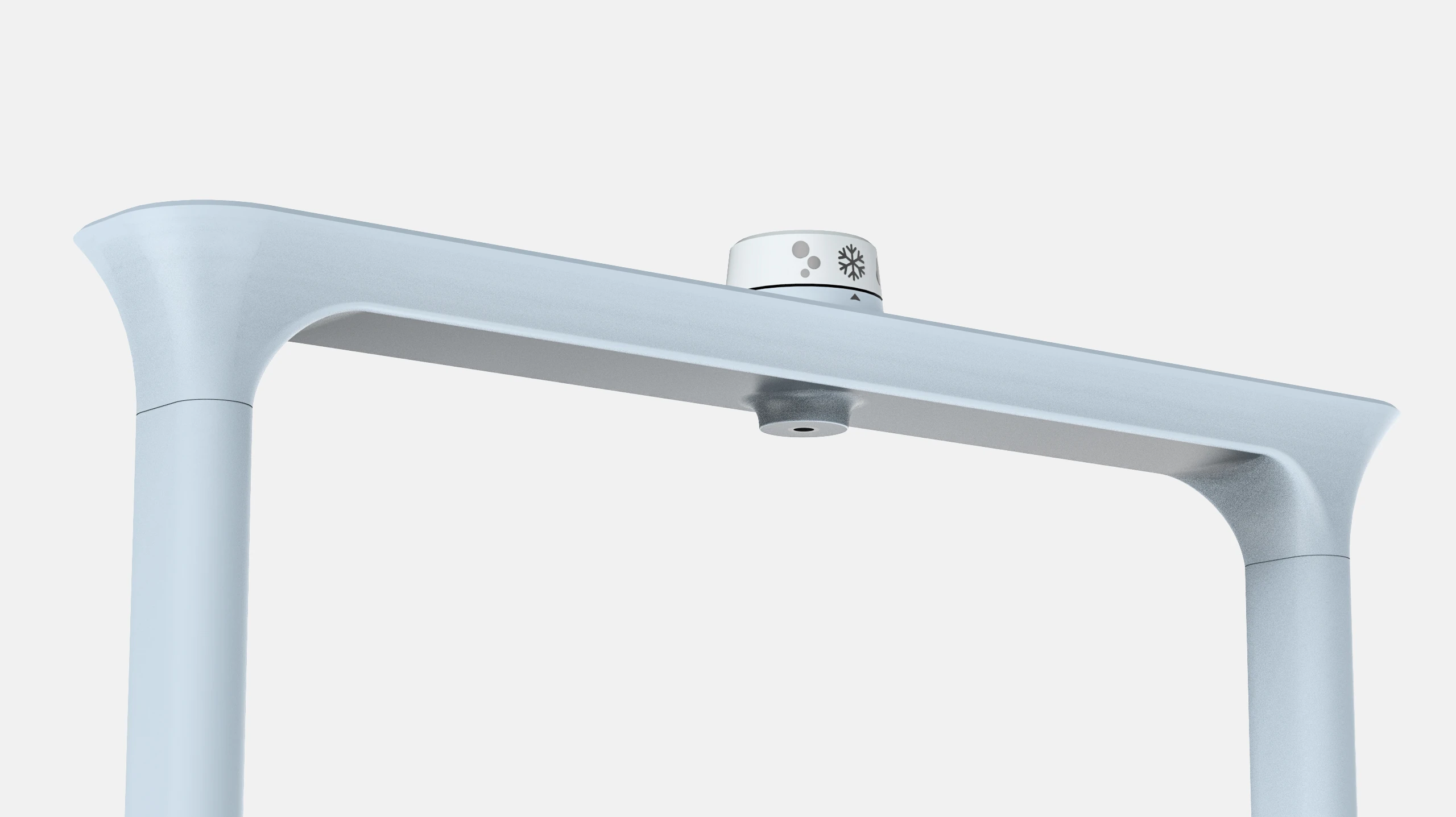

The top module is designed in the shape of a bridge, a parallel with the water flowing beneath it. The surfaces are seamlessly blended to allow for easy cleaning. In the center of the tray, a visual and illuminated circle helps the user position the bottle accurately at the center.

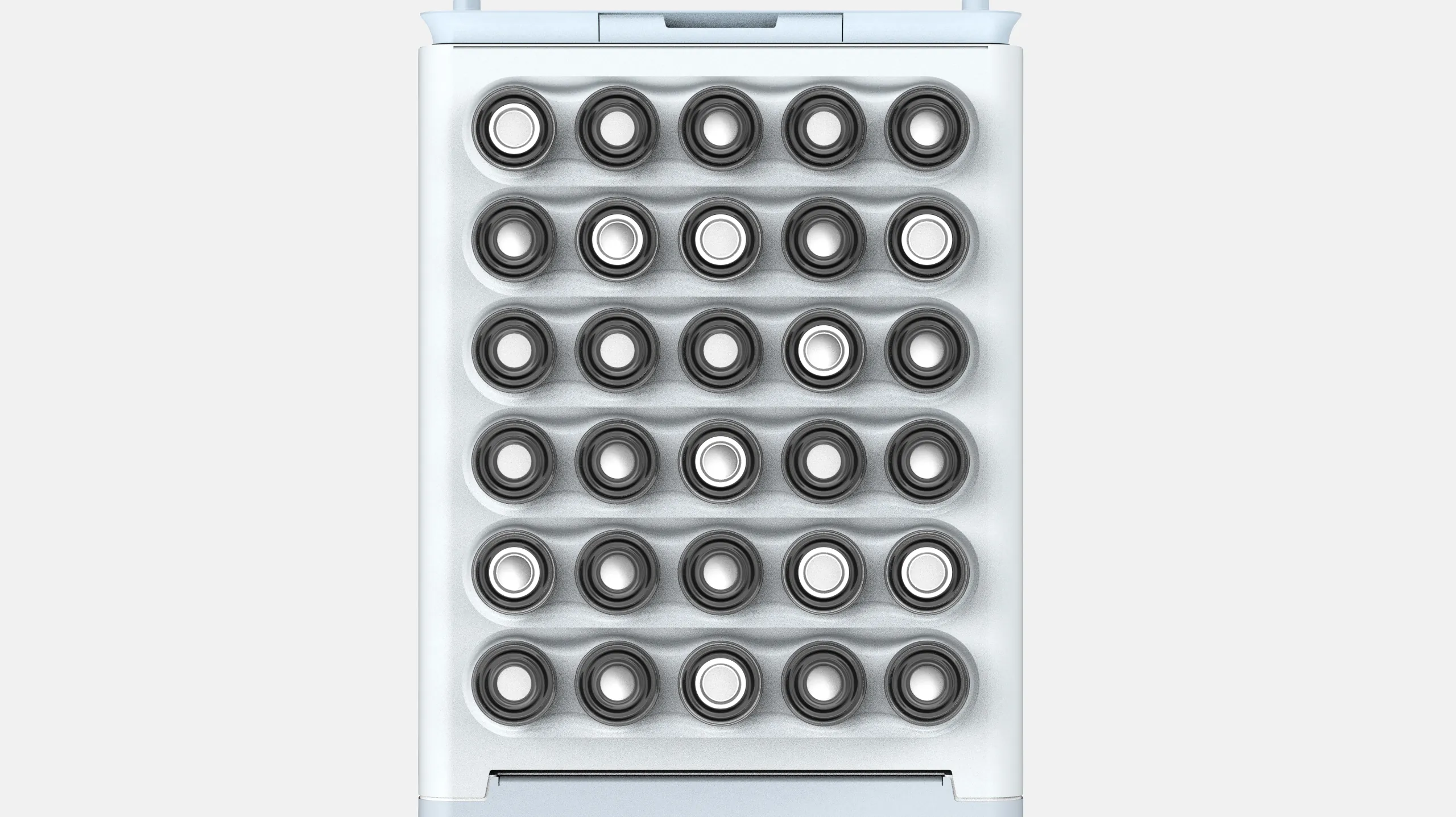

The middle module was conceived as a storage space for bottles, with the idea that they could be filled at the beginning of a shift by restaurant or café staff and then stored for later use.

The concept was well received by Midea, who nonetheless imposed a few constraints. Among them: only one type of cap, no colored lights, and no refrigeration system.

The challenge, then, was to keep the bottles cool for as long as possible, to track which ones were no longer fresh, and to distinguish between still and sparkling water.

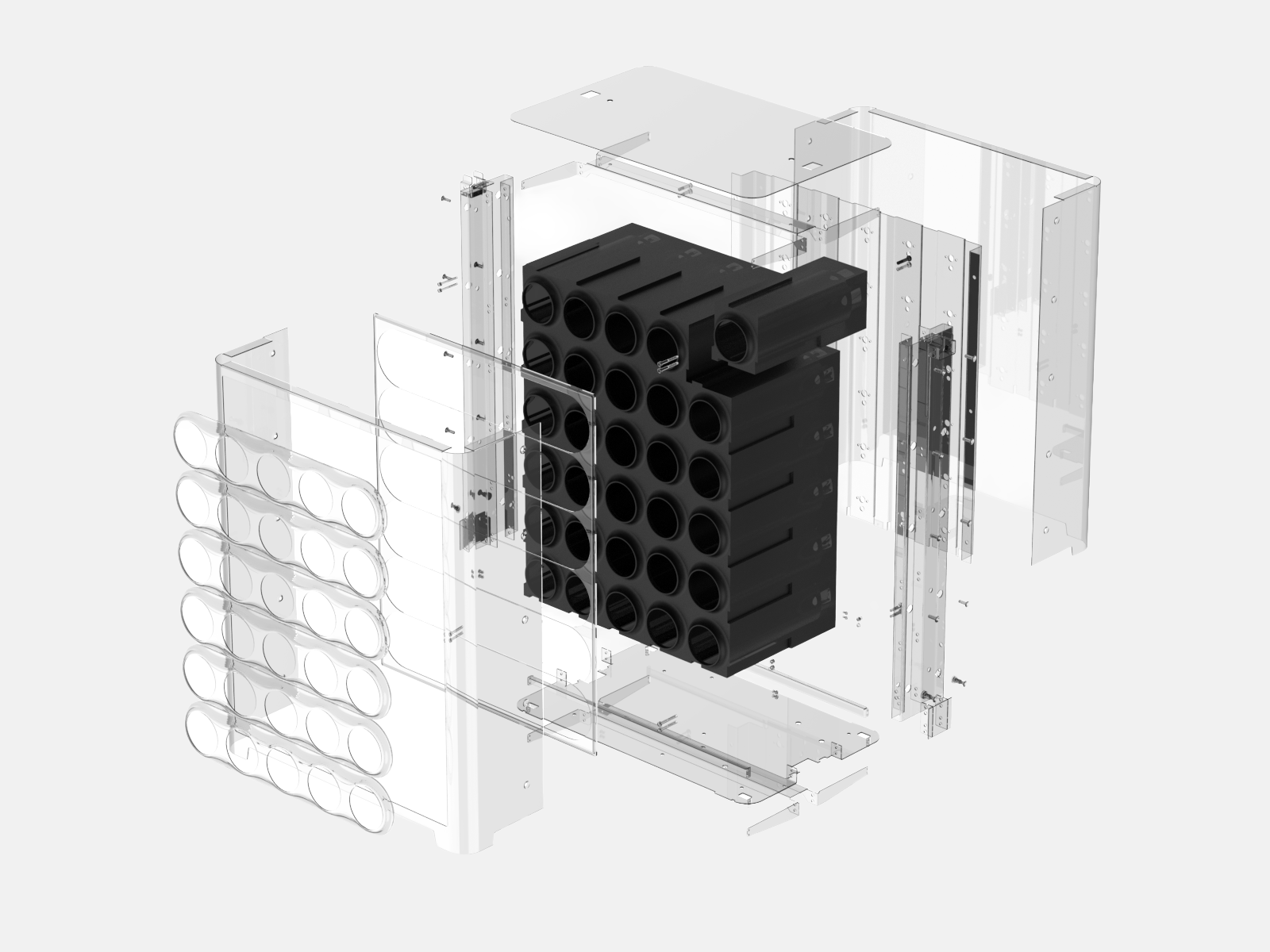

The solution to keep the bottles cool is an internal structure made of EPP, a highly insulating material commonly used in food transport. To avoid the cost of an expensive production mold, this structure is divided into several identical sub-parts. To eliminate the need for glue, these parts assemble in a puzzle-like manner.

At the back of this structure, thermal probes are positioned to make contact with each bottle. These sensors are connected to LEDs that remain lit as long as the bottles stay below 10°C.

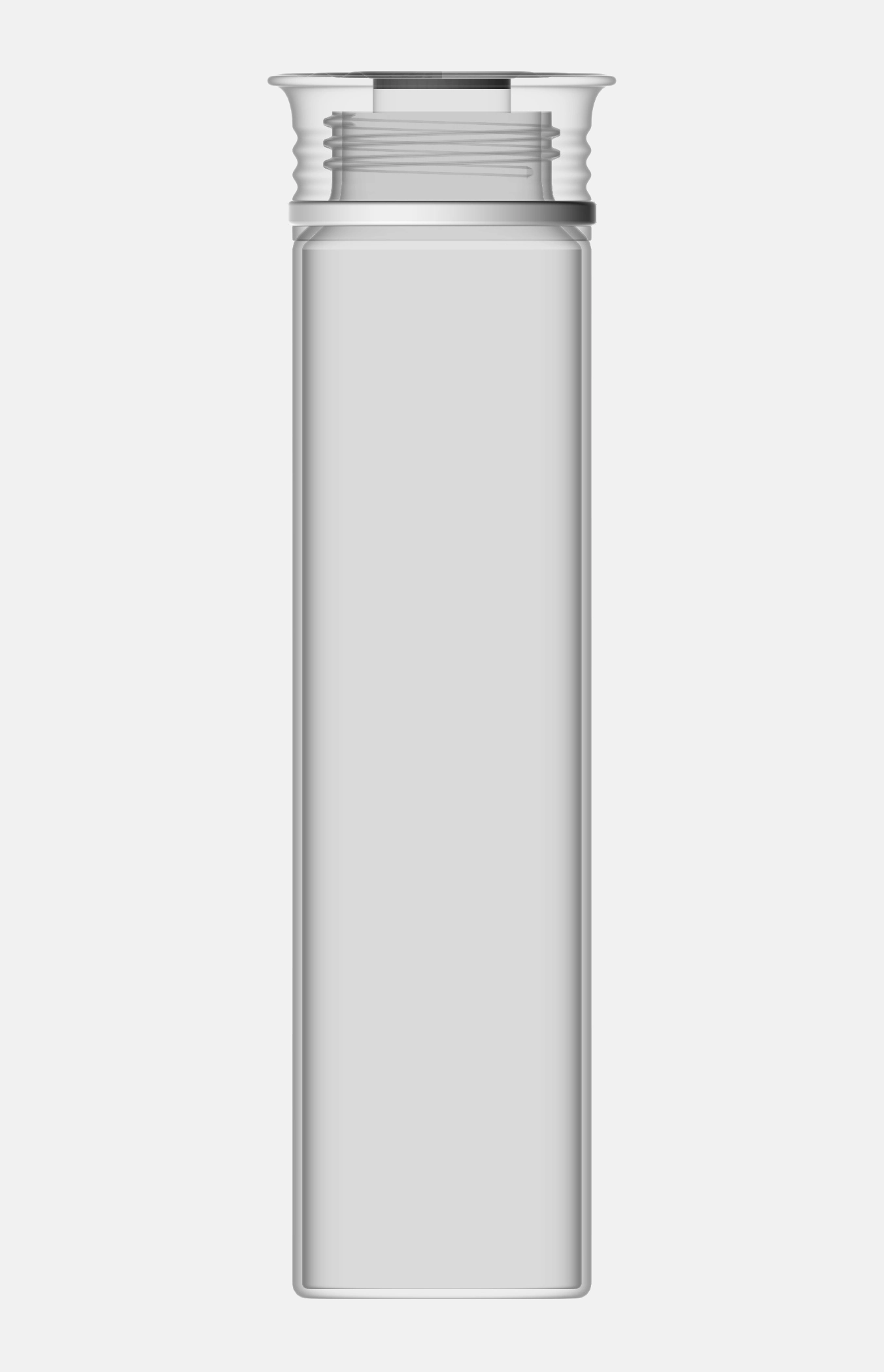

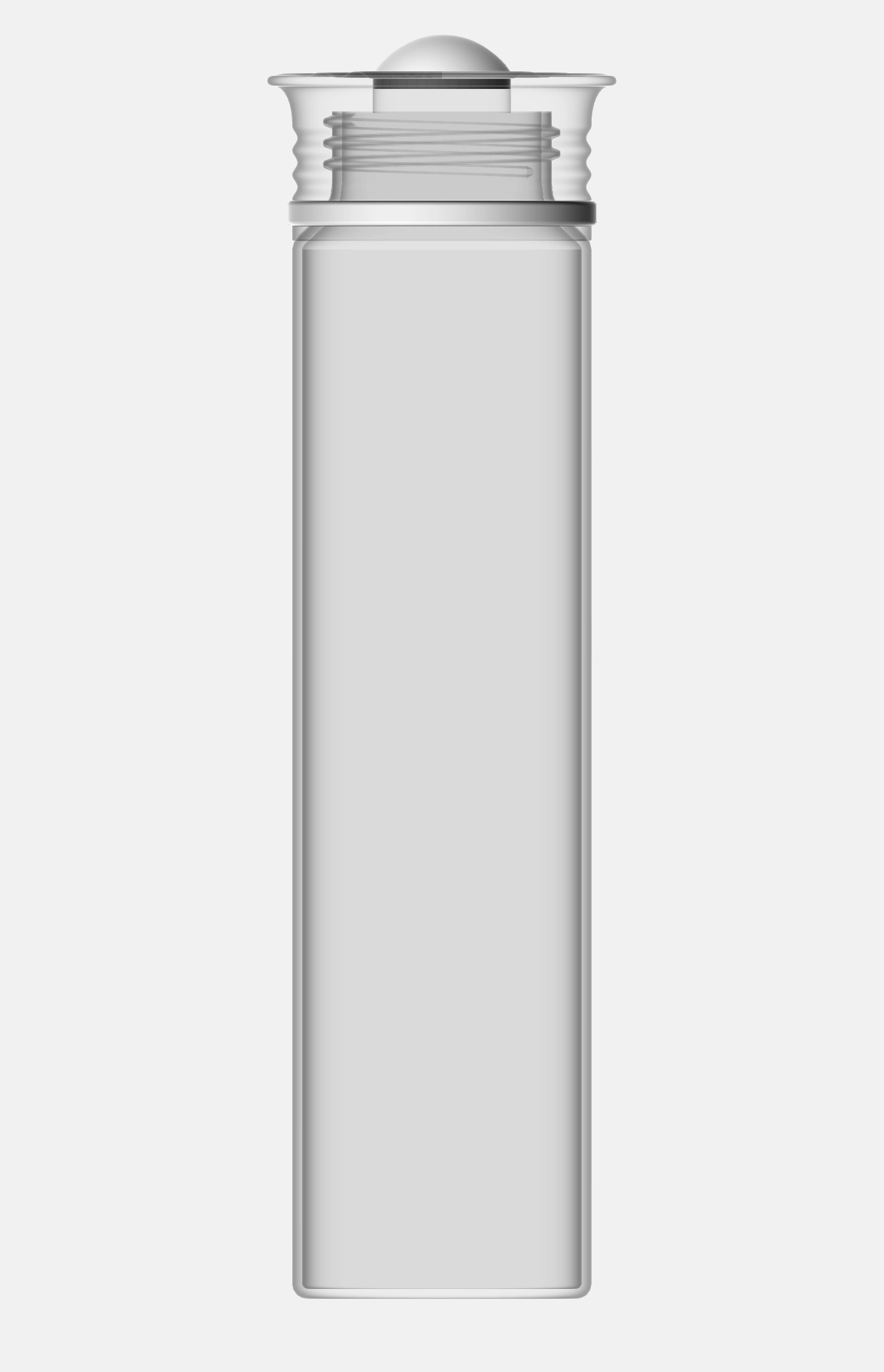

To ensure the LEDs are visible from the outside, both the bottles and their caps are transparent. Additionally, a gasket is placed around each cap to seal the EPP compartments and improve insulation.

A simple membrane system was designed to distinguish still and sparkling water: CO₂ pressure makes the membrane bulge, clearly identifying sparkling bottles.

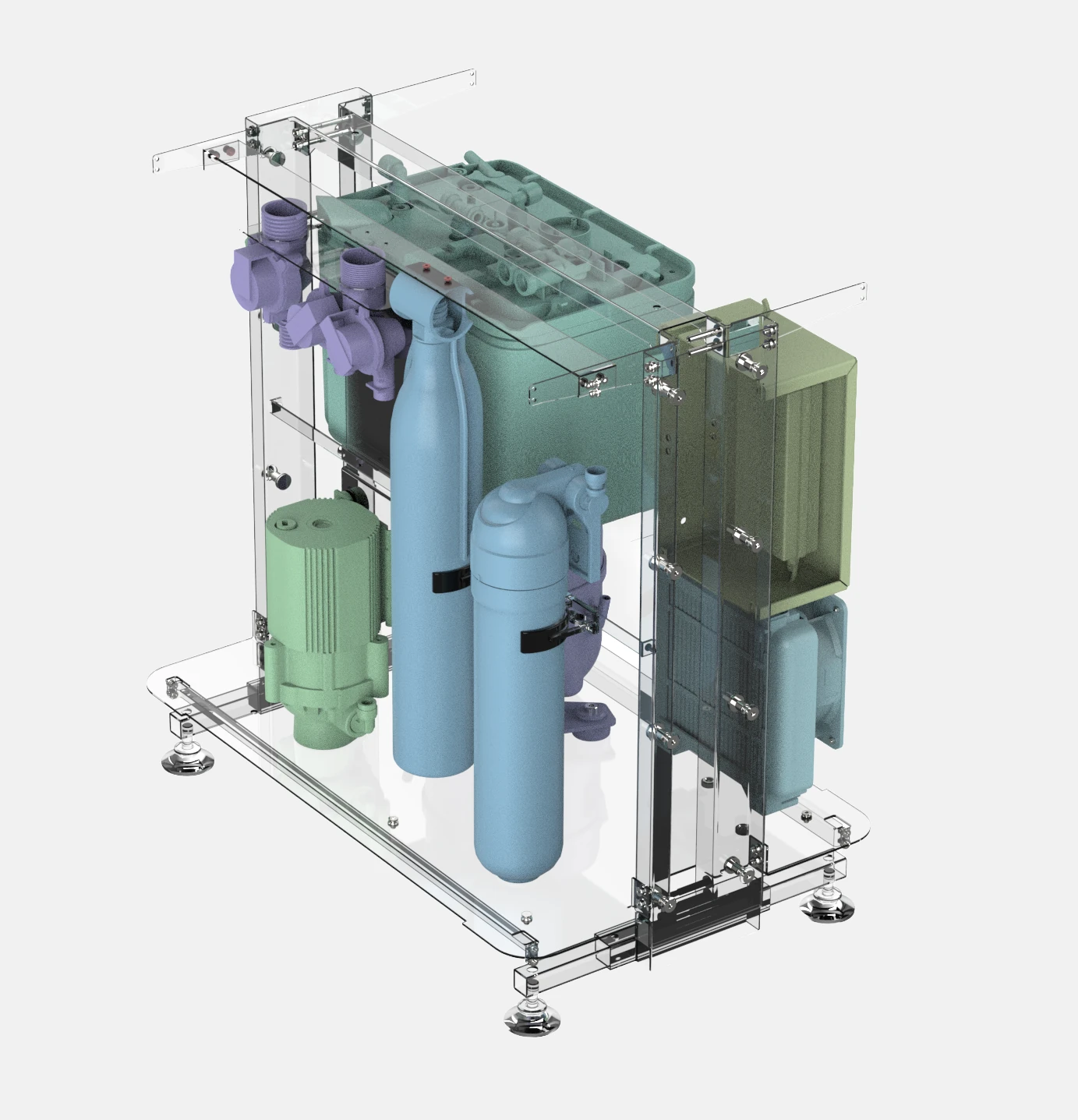

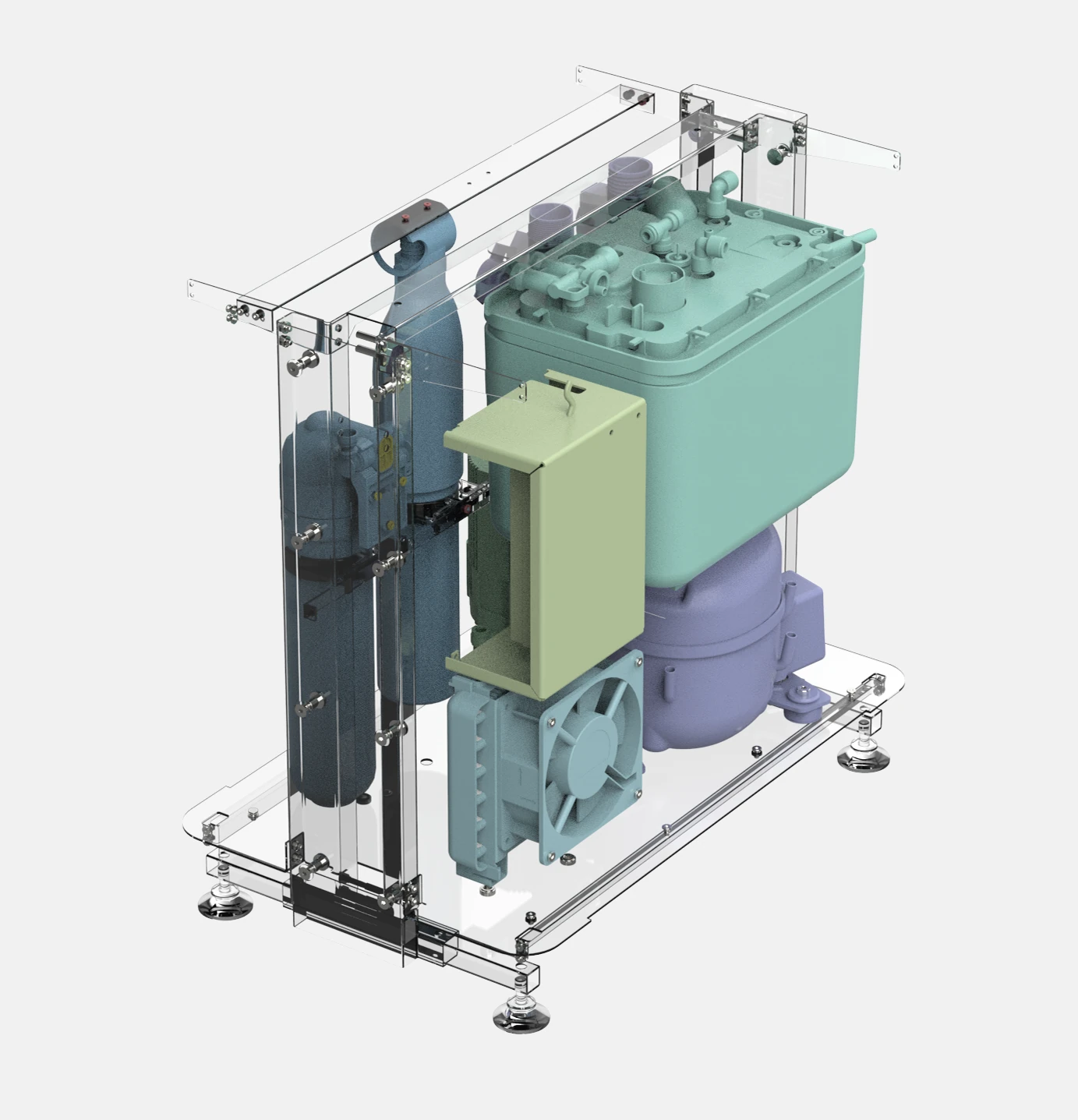

The bottom module allows easy access to the technical components through a removable panel, functioning with a simple guillotine and magnet system. The lower slot is created by folding the metal to eliminate sharp edges.

The bottom module was dimensioned and designed to house all the technical components required for water filtration and dispensing, as well as the elements needed to make the water sparkling. These components were arranged to allow easy access to the filters and CO₂ cylinders, which need to be replaced regularly.

This project was later acquired by Midea, which was a great source of pride for me.